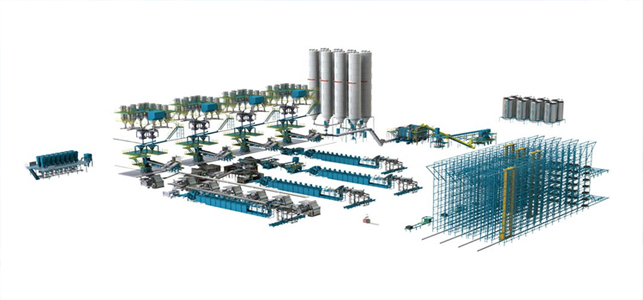

Pneumatic conveying system for a Russian petrochemical company with an annual production capacity of 300,000 tons of HDPE pellets.

• Pneumatic conveying system;

• Dilute phase open loop conveying system;

• Conveying capacity: 40 tons/hour.

In the petrochemical field, we provide integrated solutions for handling powder and granular material, with a core focus on pneumatic transportation systems.

View Details

With over 20 years of expertise in rubber mixing systems, we deliver comprehensive solutions for intelligent rubber mixing workshops.

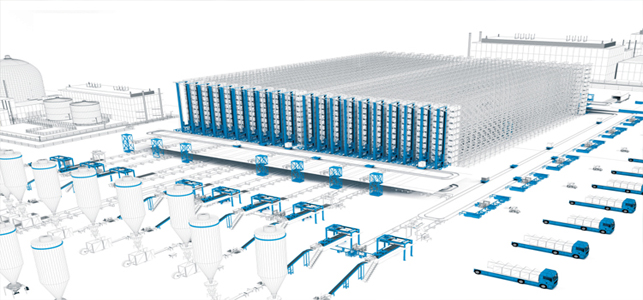

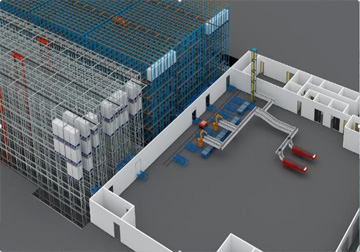

Our company optimizes upstream and downstream industrial chain to deliver intelligent logistics systems and automated storage solutions for diverse industries.

View DetailsQingdao Colt Technology Co., Ltd. (Colt) is a high-tech enterprise established with the support of the National Rubber and Tire Engineering Technology Research Center. With years of technical expertise, our team possesses core proprietary technologies and extensive experience in equipment design, manufacturing, and construction supervision, allowing us to provide clients with one-stop solutions for handling powder and granular material, centered around pneumatic conveying system.

Colt has a dedicated design team specializing in mechanical, electrical, and software solutions for the chemical and rubber tire industries. Through continuous research and innovation, we have achieved world-class standards in design, processing, manufacturing, and upgrading capabilities. We develop a range of equipment, including automatic unpacking, weighing and batching, mixing and homogenizing, stirring and dispersing, storage silos, dust removal systems, and software solutions. Our services encompass enterprise planning, equipment research and development, on-site installation and commissioning, and technical services, making us capable of serving a wide range of industries, including rubber and products, chemicals, pharmaceuticals, food, and coatings.In line with the national “Made in China 2025” initiative, Colt integrates automation technology, information technology, networking, and scientific management to offer customized smart factory and industry-wide intelligent solutions based on the Internet of Things, characterized by high levels of digitization, networking, and intelligent automation.

With years of technological advancement and talent development, Colt adheres to the principles of balancing technology and quality, focusing on customer service, and cultivating industry-leading projects. Leveraging our extensive experience in chemical machinery design, research and development, and technical services, we are committed to becoming a global provider and partner of comprehensive solutions for our clients.

Featuring proprietary patented technology, this machine achieves a raw material discharge rate of 99.9%. It utilizes a mechanical standard hook to handle various types of packaged granular or powdered materials.

View Details

The automatic unpacking process is fully enclosed during both the bag-breaking and material separation stages. Each step includes a dust removal device, ensuring no dust leakage and low noise, thereby improving the working environment.

Specifically designed for storing materials in space bags, the unloading unit serves as a transitional passage for materials entering the transportation unit. It offers high unpacking efficiency and minimizes environmental contamination.

View Details

Facilities transportation and installation with a modular assembly design.

View Details

Constructed from stainless steel, featuring corrosion-resistant and low resistance.

Capable of transporting high-viscosity materials and designed for easy installation.

• Pneumatic conveying system;

• Dilute phase open loop conveying system;

• Conveying capacity: 40 tons/hour.

• Silo project;

• Project includes: 14 silos;

• Material: Aluminum alloy.

• ASRS (Automated Storage and Retrieval System)

• AGV intelligent handling system;

• Rail Shuttle Storage System;

• Intelligent sorting system.