In order to better serve the petrochemical, rubber and plastic, new energy and emerging industries, and to meet the requirements of various industries for efficient, energy-saving, safe and environmentally friendly automated production in the transportation, storage, mixing, weighing and packaging of different powdered and granular chemical raw materials and auxiliary materials, the company has built Asia's only and internationally advanced intelligent bulk pneumatic conveying and high-precision batching R&D center. This center comprises a pneumatic transportation technology and equipment laboratory, a batching technology and equipment laboratory, an intelligent pneumatic transportation engineering experimental platform for powders and granules, and a high-precision batching weighing engineering experimental platform.

Once the equipment developed by the company is completed, it is initially tested in the pneumatic transportation technology laboratory, which primarily focuses on research related to pneumatic transportation theory. This includes studies on the properties of transportation materials, methods and states of pneumatic transportation, and specialized pneumatic transportation applications. The pneumatic conveying equipment laboratory applies the theoretical research findings to the development of equipment, including the design of bulk handling equipment, ventilation systems, valve development and improvement, and silo equipment. Equipment validated in the laboratory is installed at customer sites to ensure stable performance and achieve the expected design outcomes.

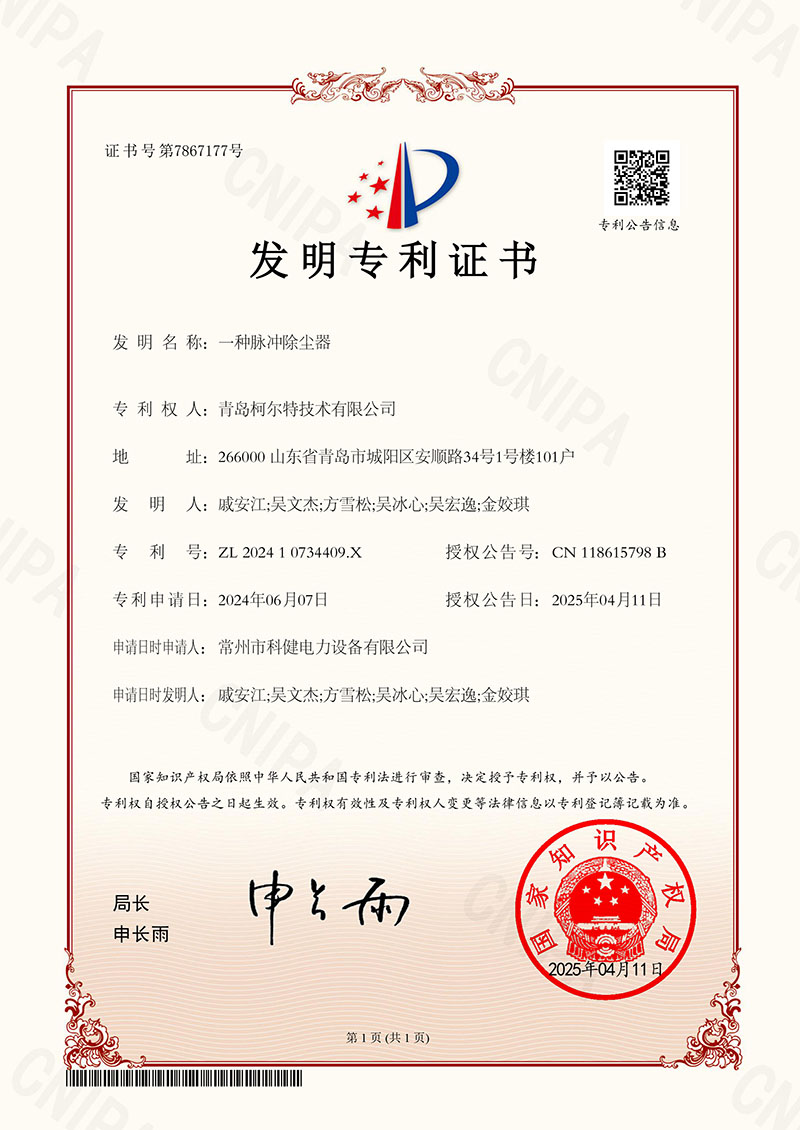

Patent for pulse dust collector

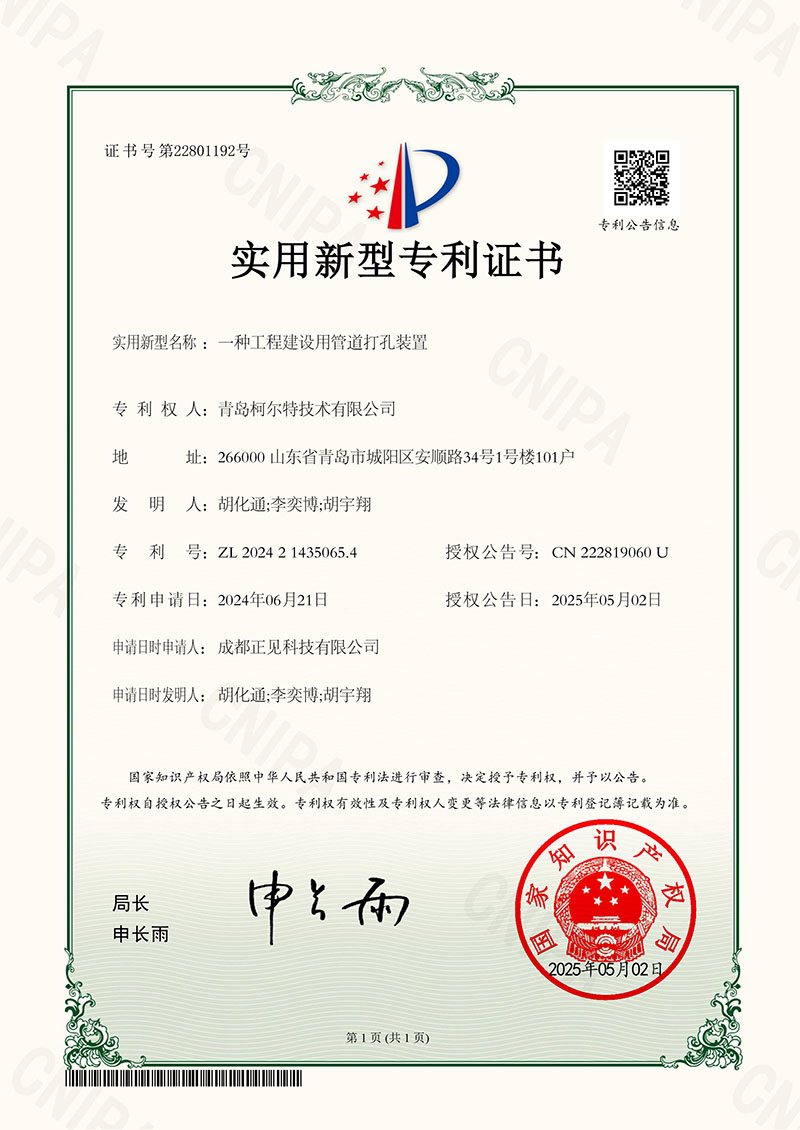

Patent for Pipeline Drilling Device

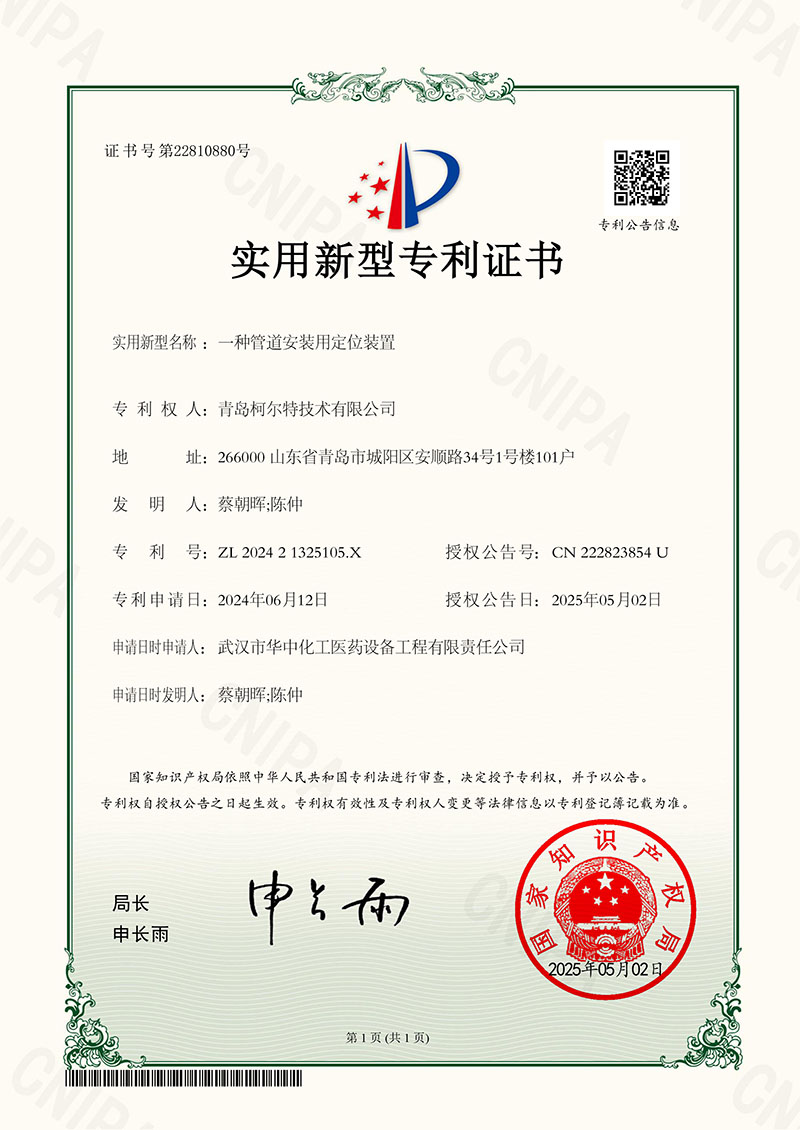

Patent for pipeline installation positioning

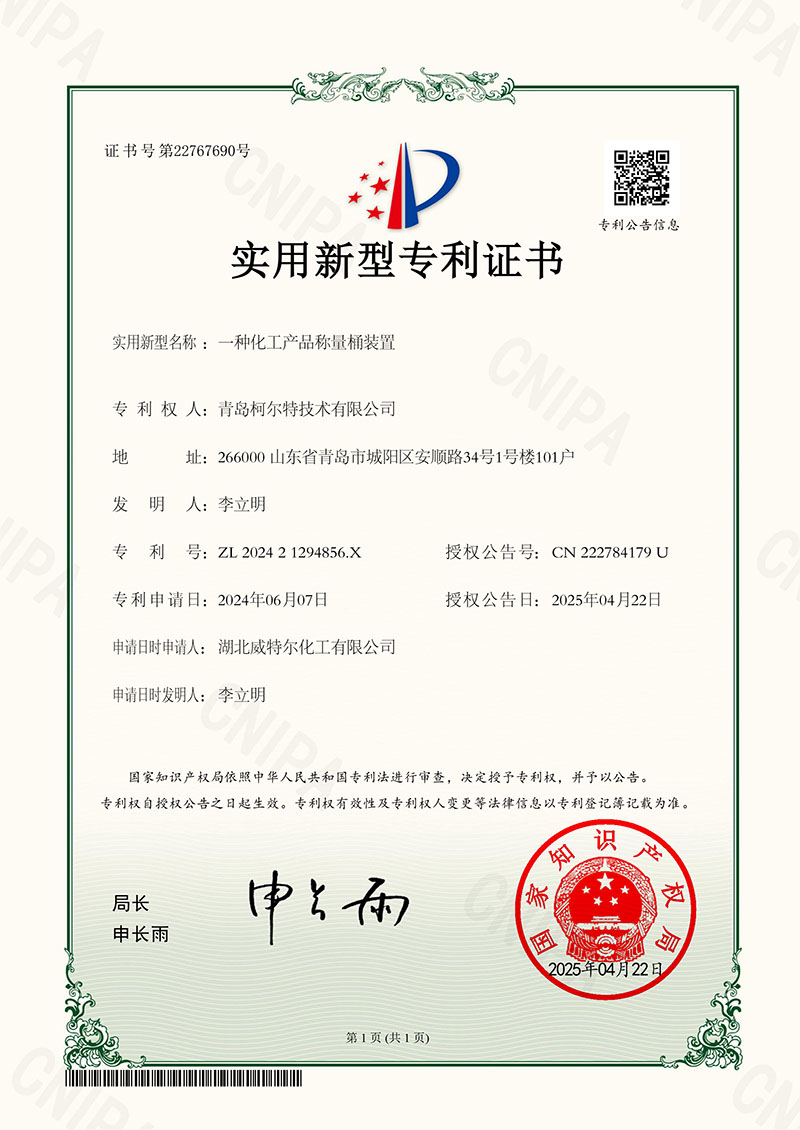

Patent for weighing bucket device

Registration of pneumatic conveying

Quality management system

Environmental management system

Occupational Health and Safety Management System